Food industry

Home > Sectors of activity > Food industry

What are the hygiene processes to use to limit health risks?

The food industry is a high-stakes sector, concerning cleaning and disinfection, in particular for packaging areas, clean rooms, etc. In the medical field there is an essentially health-based risk, but in the food industry the risk is also financial because it is linked to the production quality of the end products. How to control health risks Oxy’Pharm has set up a complete hygiene concept with steam bio-cleaning and automated biodesinfection. Treatments that meet current standards, are fully biodegradable and safe for the health of the end consumer.

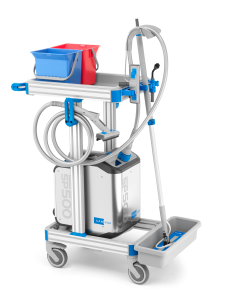

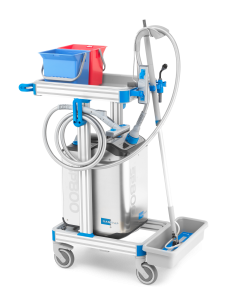

Sanivap,

steam bio-cleaning

A study performed in collaboration with the CNTSV (National Training Centre for Technicians in Veterinarian Services) confirms the benefit of using the Sanivap steam method and makes it a powerful tool for managing safety in the food industry. The results obtained are unanimous and confirm that this method is a very relevant technique that can be used by those in charge of implementing a hygiene plan in the food industry. The versatility of steam is used to treat all types of surfaces that are suitable for steam bio-cleaning. The variety of accessories available makes it easier to access hard to clean areas. The devices are chemical-free and have no risk of residual product on the cleaned surfaces.

Nocotech,

automated bio-disinfection

The bio-disinfection function is a key factor in the food industry. Food security issues have become an important part of modern society. In order to meet these increased requirements, the Nocotech solution reduces the microbiological risks, therefore protecting the end consumer. An automated solution based on the dual action of a treatment device and a disinfectant or insecticide product. The treatment is completely biodegradable, environmentally friendly and safe.

Glosair,

automated bio-disinfection with advanced technology

The Glosair solution is also based on the dual action of an automated surface treatment device and a disinfectant product. The difference is that it is a high-tech solution that makes it easier to control and trace all of the treatments. The Glosair solution therefore allows for high-quality follow-up of users.